Advantages

- Broad UV/VIS/NIR spectral range

- Wide range of core and cladding geometries (e.g.,square, rectangular, or octagonal)

- Homogeneous power distribution

- Very low NA expansion

- Excellent image scrambling characteristics

- No need for laser beam-shaping optics

- High resistance against laser damage

- Step-index profile

- Biocompatible material

- ISO9001 compliant manufacturing environment

- 500 ArmD™ UV and ArmD™ WF fibers in stock Non-standard diameters and NA values available

- Option of fully customized fiber production

- CE mark

- Sterilizable using ETO and other methods

Attenuation

The following diagrams provide an overview of attenuation values relative to the wavelengths:

Applications

The preferred option for applications such as laser surface treatments, astronomy applications, and numerous others.

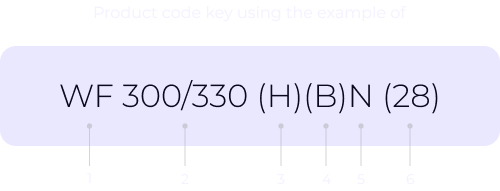

- Fiber type - UV = ArmD™ UV | WF = ArmD™ WF | WFGE = ArmD™ WFGE | HUV = ArmD™ HUV | HWF = ArmD™ HWF

- Standard core / cladding ratios - Core ø (μm) / Cladding ø (μm)

- Buffer - H = hard polymer buffer | No information = silicone buffer

- Colour - B = black | BL = blue | W = white | Y = yellow | R = red | G = green | No information = transparent

- Jacket material - A = acrylate jacket (no buffer) | F = PFA Fluon® | N = nylon jacket (silicone or hard polymer jacket) T= ETFE jacket (silicone or hard polymer buffer) | P = polyimide jacket (no buffer)

- Numerical aperture (NA) - 12 = 0,12 | 28 = 0,28 | No information = 0,22 (standard)